Sludge level sensors

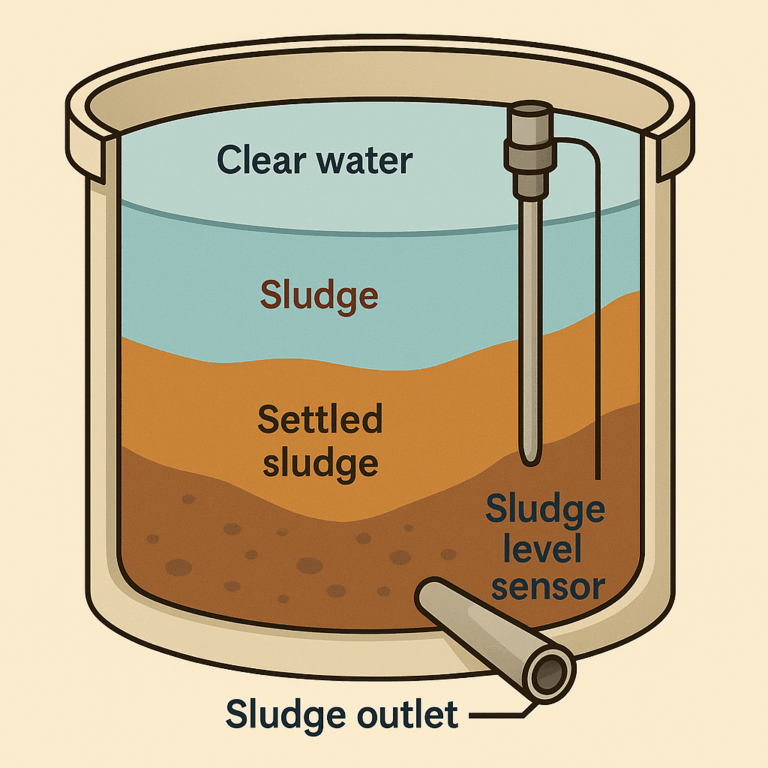

Imagine a secondary clarifier. It looks calm – clear water on the surface, like nothing’s happening. But below? That’s where the action is. Wandering flocs, settling water, descending activated sludge, and sometimes – a dramatic buildup that can throw the whole process off balance. And that’s exactly where they come in – sludge level sensors.

📏 Why measure sludge level?

- maintaining proper sludge retention time,

- preventing sludge rising (also known as “bulking”),

- controlling the process of sludge recirculation and excess sludge removal,

- ensuring stable operation of the bioreactor.

Back in the day – people used to eyeball it, measure with a stick, or glance from the walkway. Today, we have precise sensorsthat deliver real-time data – and can even control pumps automatically.

🔍 What types of sensors are used?

Ultrasonic sludge blanket level sensors

They operate based on echolocation – emitting a sound wave and measuring the time it takes to reflect off the sludge interface.

Advantages: non-contact, low-maintenance, and fairly accurate in clear conditions.

Disadvantages: interference from foam, mist, or overly dense sludge.

Optical (optoelectronic) sensors

They detect the sludge level based on how suspended solids scatter light.

Advantages: more accurate than ultrasonic sensors, and well-suited for detecting multiple sludge layers.

Disadvantages: require regular cleaning and are more expensive.

Pressure (hydrostatic) sensors

They measure changes in hydrostatic pressure caused by sludge density.

Advantages: good for continuous measurement and resistant to foam.

Disadvantages: sensitive to contamination and challenging to calibrate.

Multi-channel sensors (e.g., SLI-05, Cerlic, Markland)

They can measure the levels of clear water, suspended solids, and activated sludge separately.

Advantages: comprehensive data and integration with SCADA systems.

Disadvantages: high cost.

🔄 What to do with this data?

- controlling the recirculation pump and excess sludge,

- alarms triggered when sludge levels exceed limits,

- data reporting and archiving,

- integration with SCADA or PLC systems.

ChatGPT powiedział: Practical example? At one treatment plant, the excess sludge pump was controlled based on the average sludge level measured over 12 hours. Result? A 15% reduction in organic load in the effluent.

🛠️ What to watch out for during implementation?

- Contamination: Every sensor requires cleaning.

- Location: Installation in a location free from foam and interference.

- Calibration: Necessary for varying operating conditions.

- Backup measurement: It’s worth having manual verification (e.g., using a measurement cylinder).

✅ Summary

Sludge level sensors aren’t just a trend – they’re a real tool for operators. They help act precisely, respond faster, and sleep more peacefully.

Are they expensive? Yes.

Do they break down? Sometimes.

Is it worth it? When they save the bioreactor from bulking even once – absolutely.

How do you rate this story?

Click the star and rate Zdzichu!

Votes: 3 · Average: 4.7

No one has voted yet. Be the first!