"Silence in the sewer: passive methods of odor reduction".

🌍 Introduction: when the sewage system starts to smell too strong

You don't have to be an odor expert to sense that something is wrong. Sewage odor is not only a matter of comfort, but also of health, social relations and... the image of the treatment plant. At a time when wastewater treatment plants are increasingly adjacent to residential neighborhoods, minimizing odor nuisance is not a whim, but a technological and legal necessity.

In this article we will look at passive methods of odor reductionsuch as biofilters, encapsulation or neutralization, which are increasingly being used as a first line of defense. We will discuss the principles of operation, pros and cons, as well as specific implementations in Poland.

🧰 What are odors and where do they come from?

Odors at the treatment plant are mainly volatile sulfur compounds (e.g., hydrogen sulfide, mercaptans), ammonia, as well as aldehydes, ketones and other organic compounds. They are formed as a result of Decomposition of organic substances under anaerobic conditions, i.e. wherever there is a lack of oxygen - in channels, chambers, retention tanks, or sludge thickeners.

Not only do they smell bad - they can also be toxic, corrosive and pose a danger to workers and nearby residents.

🛠️ Hermetization - the first line of defense

The simplest, but often most effective way to reduce odor emissions is to physical isolation places of their formation. Airtight lids, tensioned membranes, steel covers - all elements of airtightness of tanks, wells and channels.

- Advantages: Simple design, adaptability to existing facilities, protection of people and equipment.

- Disadvantages: The need to provide ventilation and discharge of collected gases, regular maintenance.

In many treatment plants, encapsulation is the basis for further operations - such as bringing air to the biofilter.

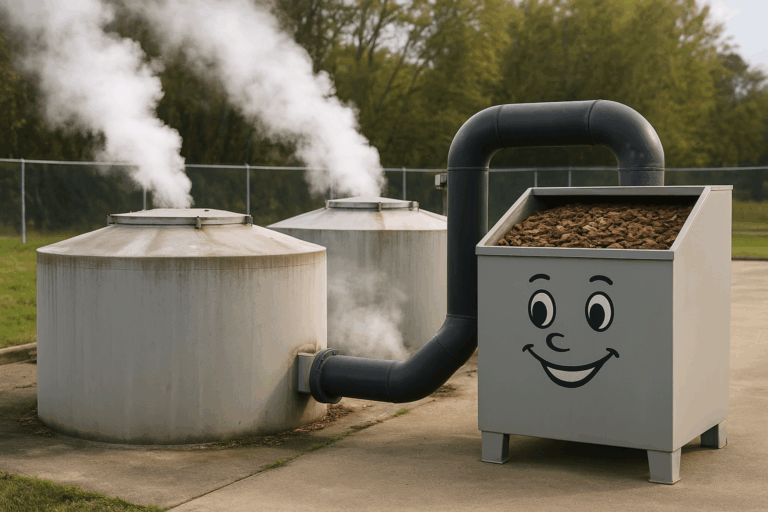

🌿 Biofilters - nature in the service of clean air

A biofilter is a structure in which polluted air is passed through a layer of biological material (e.g., wood bark, peat, compost), populated by aerobic bacteria. These microorganisms break down odorous compounds to less noxious ones - most commonly CO2, H2O, sulfates, nitrates.

Types of biofilters:

- Open: With a biological layer on the outside, such as at digesters.

- Covered: in an enclosure, often with controlled temperature and humidity.

Performance requirements: constant humidity, temperature above 10°C, no substances toxic to bacteria (such as solvents).

🔧 Chemical neutralization and adsorption

Another approach to reducing odors is their Adsorption (e.g., on activated carbon) or chemical neutralization Using neutralizing mists, such as those containing plant oils, chlorine oxides, peroxides.

- Activated carbon: good solution for low concentration gases, requires regular replacement.

- Mists: rather as support, because they act locally and short-term.

This is a good complement to encapsulation or biofiltration in hard-to-reach areas.

🏛️ Examples from Poland: who has already done it?

- Auschwitz: The plant used compost biofilters to neutralize air from the digesters. The reduction of H2S reached 95%.

- Krakow - Plaszow: Hermetization of expansion wells and supply of air to the adsorption system on activated carbon.

- Piaseczno: Fog neutralization based on plant extracts in the area of sewage wells.

✅ Summary: odors under control

Passive odor reduction methods are not only a way to clean air, but also to calmer social relations i better PR of the treatment plant. Although they require expenditures, they pay off quickly - not only financially, but also in terms of image and operations.

In subsequent articles, we will look at active methods - including bio-ozonation, low-temperature plasma and photochemical catalysis. See you on Tuesday!

How do you rate this story?

Click the star and rate Zdzichu!

Votes: 2 · Average: 5

No one has voted yet. Be the first!